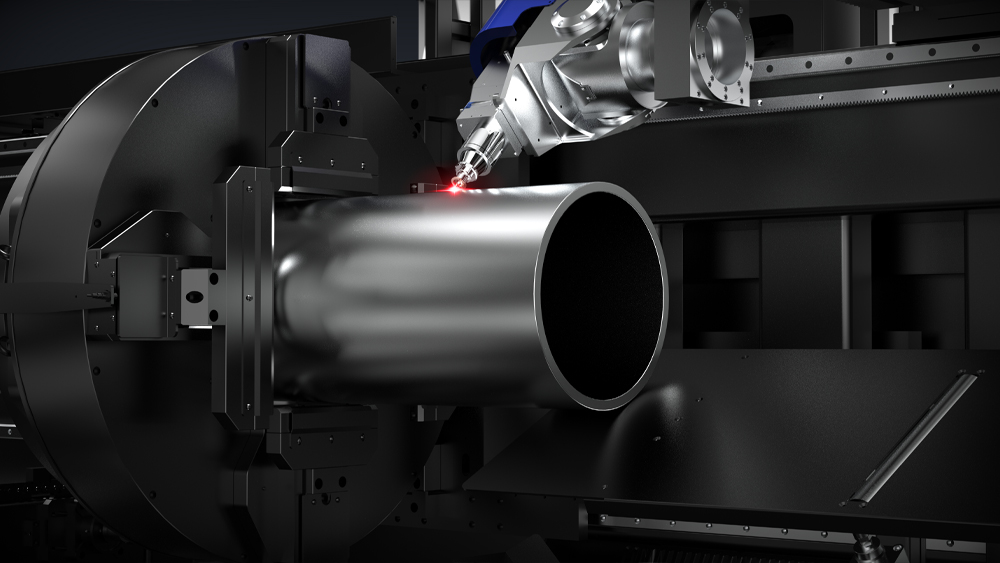

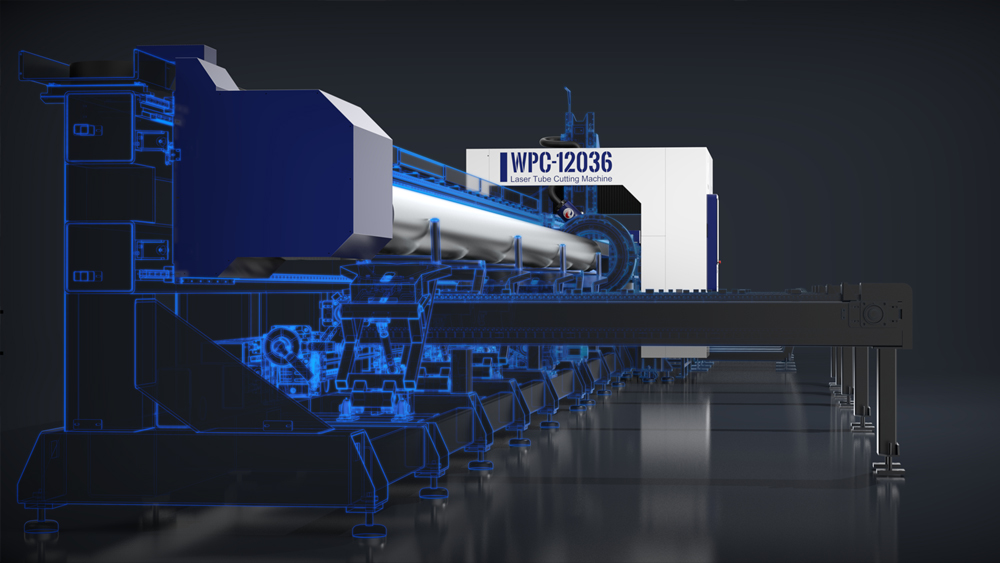

Die WPC CE-Serie kann Rohre mit großem Durchmesser, hoher Beanspruchung und extrem langer Länge effizient schneiden.

Modell :

WP12036C/12050C/12065CTischreisen :

9000-12000mmA/P-Achse dreht sich :

N×360°Wiederholgenauigkeit der Linearachsenposition :

±0.03mmMaximale Geschwindigkeit der Linearachse :

72m/minMaximale Geschwindigkeit der Drehachse :

75rpmWiederholgenauigkeit der Drehachsenposition :

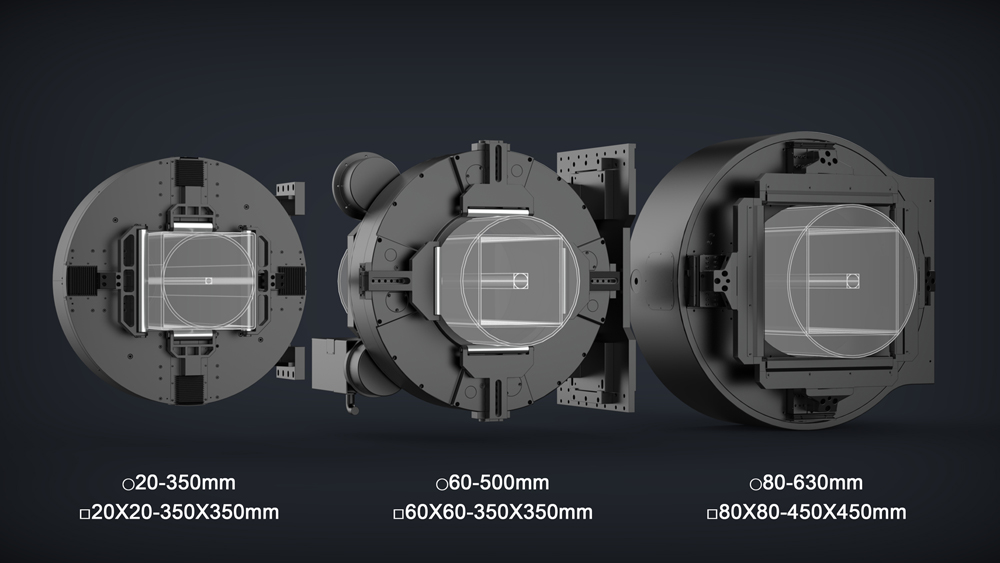

±8arc minRohrdurchmesserbereich :

Φ20-630mm □20×20-450×450mmMaximale Verarbeitungskapazität :

1200kg/2400kg/3000kgFasenschneiden :

OptionalLaserleistungsoption :

3-20kWBetriebssystem :

Smart managerLaser-Rohrschneidemaschine der WPC-Serie

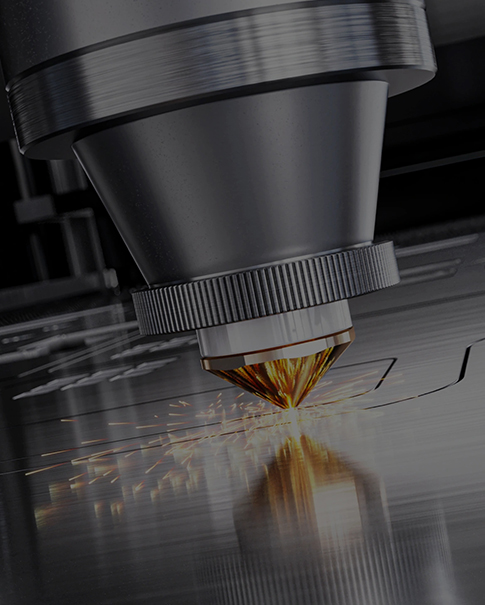

Die Laser-Rohrschneidemaschine der WPC-Serie ist für das Schneiden von Hochleistungsrohren konzipiert. Sie verfügt über eine maßgeschneiderte große Öffnung und ein seitlich hängendes, hochbelastbares Spannfutter mit einer maximalen Tragkraft von 1,2 Tonnen. Die Maschine ist standardmäßig mit einem halbautomatischen Ladesystem ausgestattet. Die Ladestütze ist mit einer Vorrichtung mit hoher Spannkraft ausgestattet, um die Zentrierung der Rohrbeladung zu gewährleisten. Die Ladeseite wird von einer servogesteuerten, schwimmenden Stütze, die Entladeseite von einer servogesteuerten, flachen, schwimmenden Stütze gestützt. Die Fasenschneidefunktion ist optional. Die Maschine entspricht den CE/UL-Designstandards in Europa und den USA. Der vollständig abgedichtete Schneidbereich mit dreifacher Sicherheitsverriegelung gewährleistet absolute Sicherheit für Elektromechanik und Laser.

Fasenschneiden

Optionale Schrägschnittfunktion.

Großer Schnittbereich

360 mm/500 mm/650 mm Spannfutter.

Seitlich montierte Bettstruktur

Anzahl der Bettverstärkungsrippen: über 100

Maximale Tragkraft: 3 Tonnen

Nachträgliche Klappenentladung

Sensibler, stabiler, präziser.

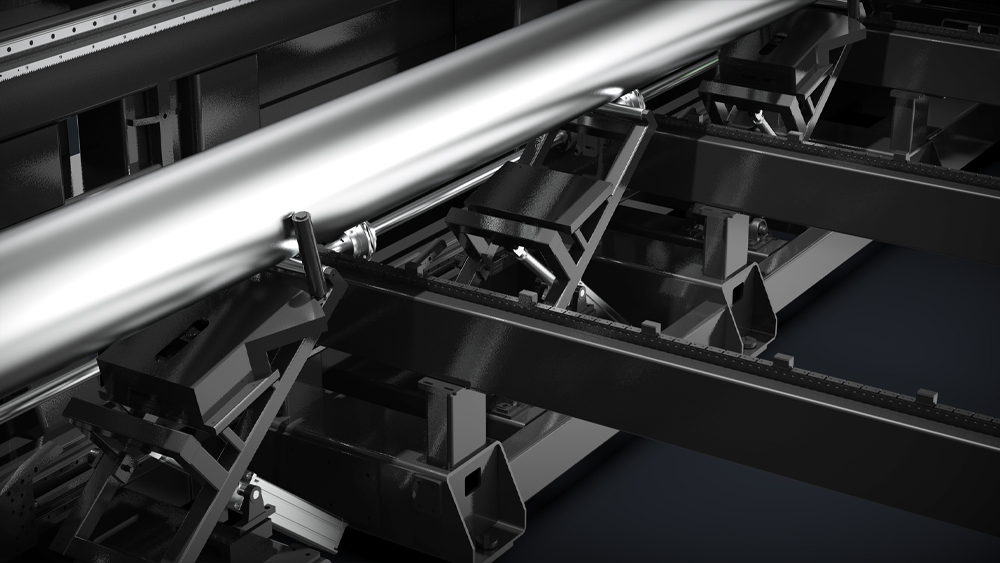

Servo-Nachverfolgungsunterstützung

Nachlaufrollenunterstützung/ intelligente Zentrierung/ genauer/ stabiler.

Halbautomatisches Be- und Entladen

Halbautomatisches Be- und Entladen

Automatisches Be- und Entladen schwerer Rohre, wodurch Kosten gesenkt und die Effizienz gesteigert werden.

Betriebssoftware

■Die neueste Version von Smart Manager ist eine in Europa entwickelte CNC-Software, die sich nahtlos in italienische CNC-Systeme integrieren lässt. Sie verfügt über eine erweiterte Laserschneiddatenbank, die die Echtzeitanpassung der Schneidparameter für optimale Schnittqualität ermöglicht.

■Der neue Algorithmus ermöglicht eine schnellere Reaktion.

■Das System unterstützt die Konfiguration von bis zu 15 Ebenen mit Schneidparametern und 25 Ebenen mit Perforationsmethoden.

Schnittprobe

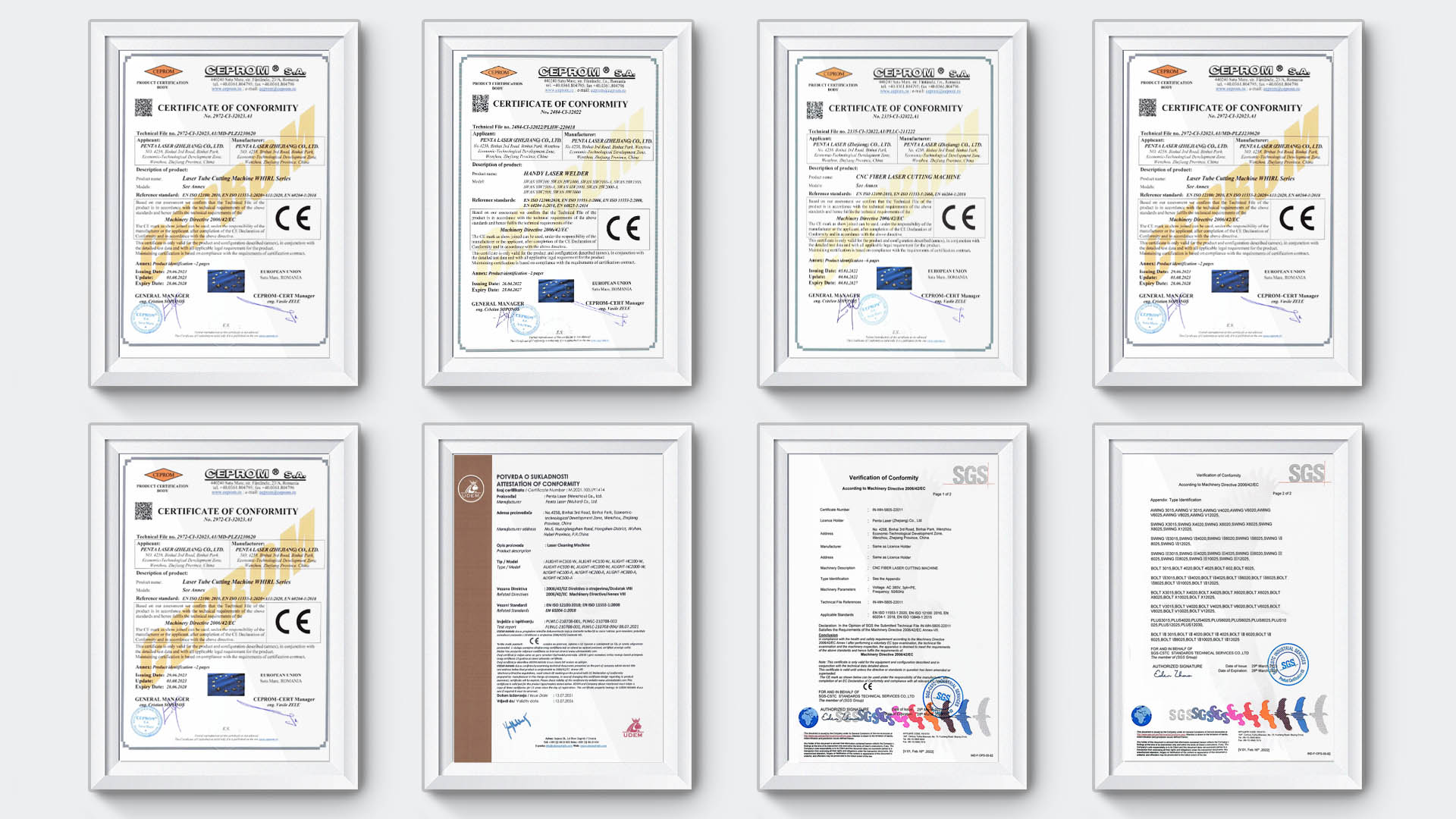

Zertifikat